Reaction Units

Reaction Units Specification

- Display Type

- Digital Display

- Shape

- Cylindrical

- Power Supply

- Electric

- Features

- Corrosion Resistant, Leak-proof, Modular Design

- Temperature Resistance

- up to 250°C

- Control Type

- Digital/Manual

- Accuracy

- ±1°C

- Glass Type

- Borosilicate Glass 3.3

- Speed Range

- 50 to 1500 rpm

- Heating Capacity

- up to 2 kW

- Type

- Reaction Unit

- Dimension (L*W*H)

- Customizable as per requirement

- Equipment Type

- Laboratory Reactor System

- Equipment Materials

- Borosilicate Glass, Stainless Steel

- Power

- 230V/110V, 50-60 Hz

- Voltage

- 230V

- Material

- Glass and Metal Body

- Application

- Chemical Reactions, Laboratory Use, Industrial Applications

- Capacity (Ltr)

- Available in 1 to 100 Ltr

- Lid Type

- Flanged with quick-release clamps

- Mobility

- Mounted on trolley/wheels

- Pressure Range

- Atmospheric to 6 bar

- pH/Temp Probe Port

- Available

- Stirring Motor

- High torque, speed controllable

- Jacketed Option

- Available

- Insulation

- Optional thermal insulation

- Thermocouple Provision

- Yes

- Inlet/Outlet Ports

- Multiple, customizable

- Agitator Type

- Anchor/Paddle/Custom

Reaction Units Trade Information

- Main Domestic Market

- All India

About Reaction Units

Explore our special Reaction Units with Stirring Motor, highlighted for their spectacular high torque and dazzling controllability. Crafted from rarefied borosilicate glass 3.3 and robust stainless steel, these units operate at atmospheric to 6 bar pressures and withstand up to 250C. The customizable agitator and modular design ensure flexibility for various chemical reactions. Featuring quick-release flanged lids, digital controls, and outstanding leak-proof insulation, our units promise rarefied efficiency across laboratory and industrial applications. Mobility is seamless, mounted on versatile trolleys, providing spectacular operational convenience and dazzling precision.

Highlighted Uses and Material Features of Reaction Units

Our Reaction Units are used extensively for chemical reactions in laboratory and industrial environments. The equipment features a modular, cylindrical design and offers customizable dimensions and agitator typesanchor, paddle, or custom. With a dazzling corrosion-resistant glass and metal body, rarefied thermal insulation, and digital temperature accuracy up to 1C, these units are ideal for processes requiring exacting control. The spectactular quick-release clamps and multiple port options make operation safe, efficient, and highly adaptable.

Reaction Units FOB Port, Export Markets, and Supply

We supply Reaction Units globally with swift dispatch from Indias major FOB ports, ensuring quick turnaround for customers worldwide. Our main export markets include Asia, Europe, and the Americas, serving both domestic and international clients. With a strong supply ability, our dazzling support network ensures uninterrupted availability. Domestic markets benefit from prompt supply and after-sales service, while distributors and wholesalers enjoy highlighted responsiveness, making us a preferred partner for both special and standard reaction unit requirements.

Highlighted Uses and Material Features of Reaction Units

Our Reaction Units are used extensively for chemical reactions in laboratory and industrial environments. The equipment features a modular, cylindrical design and offers customizable dimensions and agitator typesanchor, paddle, or custom. With a dazzling corrosion-resistant glass and metal body, rarefied thermal insulation, and digital temperature accuracy up to 1C, these units are ideal for processes requiring exacting control. The spectactular quick-release clamps and multiple port options make operation safe, efficient, and highly adaptable.

Reaction Units FOB Port, Export Markets, and Supply

We supply Reaction Units globally with swift dispatch from Indias major FOB ports, ensuring quick turnaround for customers worldwide. Our main export markets include Asia, Europe, and the Americas, serving both domestic and international clients. With a strong supply ability, our dazzling support network ensures uninterrupted availability. Domestic markets benefit from prompt supply and after-sales service, while distributors and wholesalers enjoy highlighted responsiveness, making us a preferred partner for both special and standard reaction unit requirements.

FAQs of Reaction Units:

Q: How do the customizable agitator types enhance the operation of Reaction Units?

A: Customizable agitator types, including anchor, paddle, or custom configurations, allow the Reaction Units to accommodate various chemical reactions and viscosities, ensuring optimal mixing, improved efficiency, and precise process control.Q: What are the benefits of using borosilicate glass and stainless steel in these units?

A: Borosilicate glass offers excellent chemical and thermal resistance, while stainless steel adds structural strength and durability. Combined, they provide corrosion resistance, safety, and longevity across diverse applications.Q: Where can these Reaction Units be used effectively?

A: These units are well-suited for laboratory research, pilot plant studies, and industrial-scale chemical processing, making them ideal for commercial, academic, and R&D environments.Q: What is the process for customizing port configurations and unit dimensions?

A: Customers can specify requirements for inlet/outlet ports and overall dimensions during the ordering process. Our engineering team collaborates closely to deliver tailored solutions that meet exact process needs.Q: How does digital temperature and speed control benefit users?

A: Digital control enables precise adjustment and monitoring of temperature and stirring speed, enhancing safety, process repeatability, and product quality during sensitive chemical reactions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Distillation Units Category

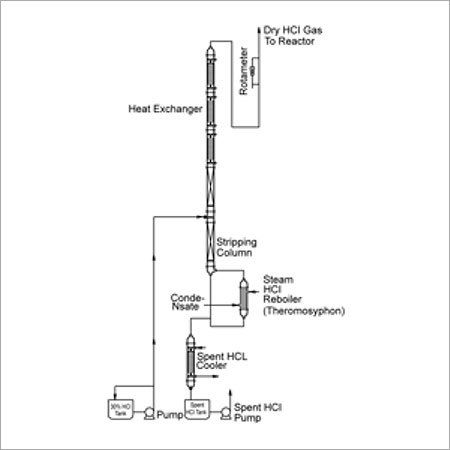

HCL Glass Generator Systems

Type : Chemical Gas Generation System, Other

Application : Used for generating dry HCL gas for reaction processes

Capacity (Ltr) : Customizable based on client requirements standard capacity options available

Material : Corrosionresistant glass and other durable materials

Glass Type : Borosilicate glass for durability and chemical resistance

Distillation Units

Type : Other, Simple Distillation Unit

Application : Chemical and Laboratory

Capacity (Ltr) : 5

Material : Borosilicate Glass

Glass Type : Borosilicate Glass

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS