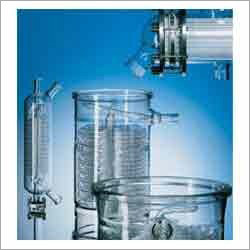

Bench Scale Reaction Units

Bench Scale Reaction Units Specification

- Heating Capacity

- Up to 2 kW (depending on vessel size)

- Shape

- Rectangular Base with Cylindrical Vessel

- Glass Type

- Borosilicate Glass 3.3

- Speed Range

- 50â1200 rpm

- Accuracy

- ±0.5°C (Temperature)

- Power Supply

- Single Phase AC

- Features

- Interchangeable vessels, precise temperature and stirring control, corrosion resistance, easy operation, safety interlocks

- Control Type

- Digital PID Controller

- Temperature Resistance

- Up to 250°C

- Display Type

- Digital LCD Display

- Type

- Bench Scale Reaction Unit

- Dimension (L*W*H)

- 600 mm x 400 mm x 900 mm

- Equipment Type

- Modular Reaction System

- Equipment Materials

- Stainless Steel, Borosilicate Glass, PTFE

- Power

- 230 W

- Voltage

- 230V AC, 50 Hz

- Material

- Borosilicate Glass 3.3, Stainless Steel 304/316

- Application

- Laboratory and Pilot Scale Reaction Studies

- Capacity (Ltr)

- 1, 2, 5, 10 Liters (customizable)

- Jacketed Option

- Double-wall for efficient thermoregulation

- Sampling Port

- Provided for process sampling

- Connectivity

- Optional RS232/USB data logging

- Pressure Rating

- Atmospheric to 6 bar

- Safety Features

- Over-temperature and overload protection

- Operating Environment

- Temperature 5-40°C, Relative Humidity ≤ 85%

- Mobility

- Fitted with castor wheels for easy movement

- Reactor Volume Options

- Customizable from 0.5 up to 20 Liters

- Stirring System

- Magnetic or Overhead Stirring

- Finish

- Electropolished for GMP Compliance

- Glassware Certification

- USP Type I, ASTM E438 Standard

- Optional Accessories

- pH/ORP sensors, condensers, feed lines, pressure gauges

- Compliance

- CE & ISO Certified

About Bench Scale Reaction Units

Bench Scale Reaction Units (with Hand Lift)

Technical Specifications

- Reactor Volume : 5L , 10L

- Reactor Type : Double Walled & Triple Walled

- Operating Pressure : Full Vacuum to 0.4 bar (g)

- Operating Temperature : -80°C to +200°C

- Thermal Shock Resistance : ( T) : 60°C for Triple

- Walled and 110°C for Double Walled Reactors

Customizable Reactor Volumes and Modular Design

Bench Scale Reaction Units offer reactor volumes from 0.5 up to 20 liters, ensuring compatibility with a wide range of research or process needs. Their modular design allows users to easily adapt the configuration for specific reaction requirements, supporting various vessel sizes and interchangeable reaction vessels.

Advanced Safety and Control Features

Equipped with digital PID controller, over-temperature and overload protection, and user-friendly LCD display, these units provide precise control and reliable safety. Their safety interlocks protect both operators and equipment, while atmospheric to 6 bar pressure rating accommodates many reaction types.

Efficient Thermoregulation and Sampling

The double-wall jacket option ensures efficient temperature control, maintaining stability for sensitive reactions. Sampling ports are integrated for convenient process monitoring and sample withdrawal without process disruption.

Corrosion Resistance and GMP Compliance

Constructed with electropolished stainless steel and borosilicate glass 3.3, the units offer excellent corrosion resistance and support GMP compliance. The glassware is certified to USP Type I and ASTM E438 standards for high performance in demanding laboratory settings.

Mobility and Data Connectivity

Designed with castor wheels for easy movement, these reaction units can be relocated effortlessly within laboratory or pilot plant spaces. Optional RS232/USB connectivity allows for streamlined data logging to improve process tracking and compliance.

FAQs of Bench Scale Reaction Units:

Q: How do I select the appropriate reactor volume for my application?

A: You can customize the reactor volume between 0.5 and 20 liters based on your process scale. Common options include 1, 2, 5, and 10 liters. Consider batch size, reaction kinetics, and sampling needs to select the optimal volume for your laboratory or pilot-scale studies.Q: What safety features are included in Bench Scale Reaction Units?

A: The units feature over-temperature and overload protection, along with safety interlocks. These mechanisms safeguard users and equipment by automatically responding to potentially hazardous situations, ensuring a reliable and secure operating environment.Q: When should I use the double-wall jacketed vessel option?

A: Double-wall jacketed vessels are recommended for reactions requiring precise thermoregulation, such as temperature-sensitive syntheses or exothermic processes. They enable efficient heating and cooling to maintain stability throughout the reaction.Q: Where can Bench Scale Reaction Units be installed within a facility?

A: These units are designed for operation in laboratory or pilot plant environments with temperatures from 540C and relative humidity up to 85%. Their compact footprint and castor wheels make them suitable for varied spaces, including research labs, quality control rooms, and education facilities.Q: What process monitoring and connectivity options are available?

A: The units come with ports for pH and ORP sensors, sampling, and optional RS232/USB data logging. Combined with the digital PID controller and LCD display, these features enable real-time process monitoring and facilitate data acquisition for quality assurance.Q: How does the electropolished finish benefit laboratory operations?

A: Electropolishing of stainless steel surfaces contributes to GMP compliance by minimizing microbial contamination and enhancing cleanability. It also improves corrosion resistance, ensuring long-term durability and safety in chemical processing environments.Q: What are the benefits of interchangeable vessels and modularity in these systems?

A: Interchangeable vessels and modular construction allow quick adaptation to changing experimental needs, support various reaction types, and streamline maintenance. This flexibility is especially valuable for research facilities and manufacturers requiring versatile setups.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Glassware Category

Glass Reactor

Minimum Order Quantity : 1 Liter

Type : Other, Glass Reactor

Material : Borosilicate Glass 3.3

Equipment Materials : Borosilicate Glass, Stainless Steel

Features : Anticorrosive, Leakproof, High Transparency, Easy to Clean, Explosion Proof

Accuracy : ±1°C (Temperature control)

Glass Nutsche Filters

Type : Other, Nutsche Filter

Material : Stainless Steel and Glass

Equipment Materials : Borosilicate Glass and Stainless Steel

Features : CorrosionResistant Easy Maintenance Portable

Accuracy : High Precision

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS